TECHNOLOGY PROVIDER FOR SMALL HYDRO POWER PLANTS

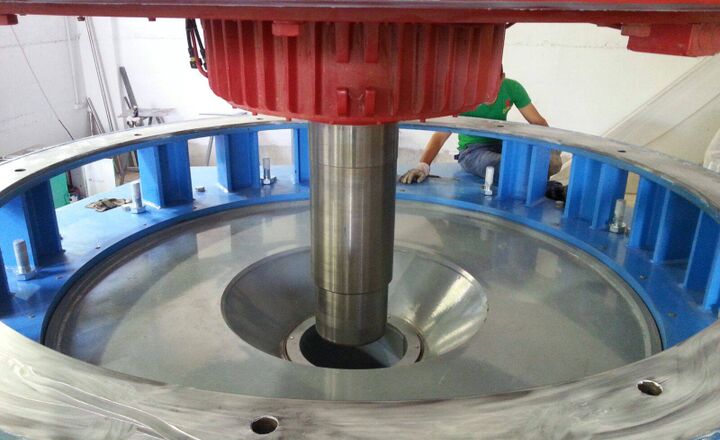

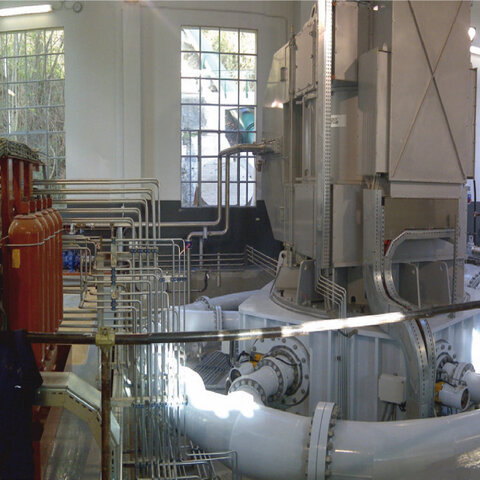

ATB Group has more than 30 years of experience, references and a proprietary expertise for the design, manufacture and installation of hydroelectric turbines.

Our organization, our skills and our know‐how are based on a long and solid experience with the main European multi-utility companies and a consolidated expertise in the low impact revamping or smart repowering of existing facilities.

We can assist investors in the preliminary design, business planning and fully customized solutions with complete internal engineering, design, fabrication and installation capabilities for:

- Hydroelectric turbines: Kaplan, Francis and Pelton from 100 kW up to 20 MW.

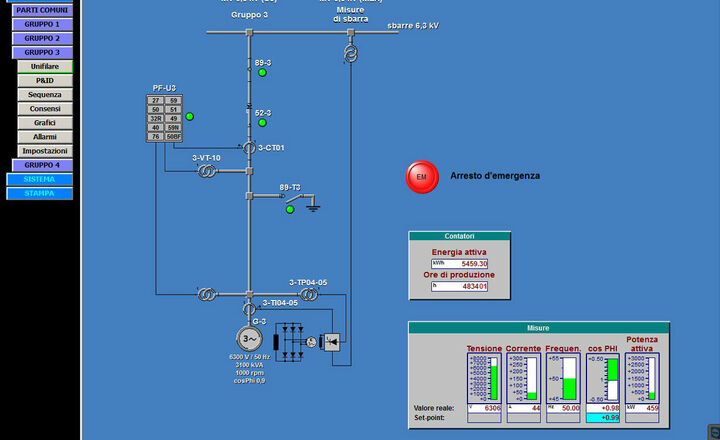

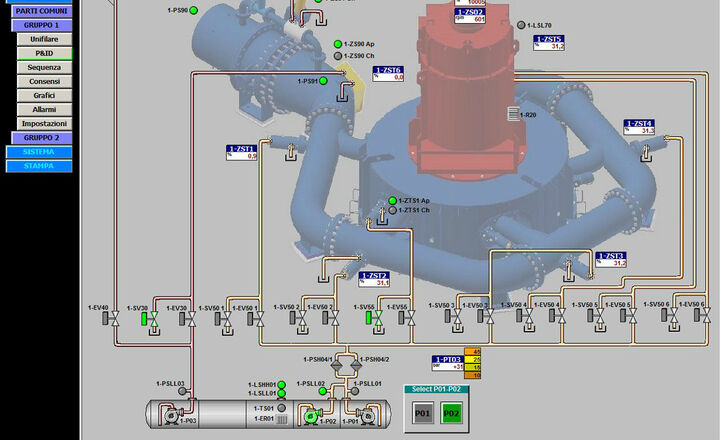

- From water to wire: Integrated solutions, with complete electromechanical equipment, electrical BOP, automation and control system.

- EPC Contractor for the supply of mini hydro power plants based upon its own technology for hydroelectric turbines.

- Specialized and customized after-sales services.

ATB Group can provide a full production cycle where each stage is developed according to the UNI EN ISO 9001:2015 standard for quality, UNI EN ISO 14001:2015 certified Environmental Management System, and UNI EN ISO 45001:2018 Occupational Health and Safety Management System.