Wind turbine manufacturing and service

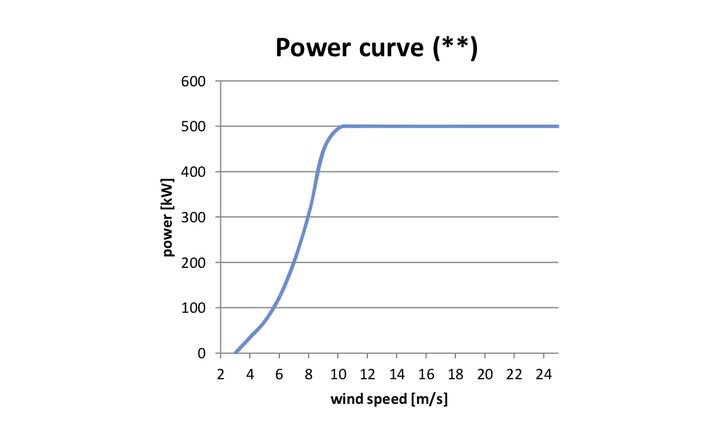

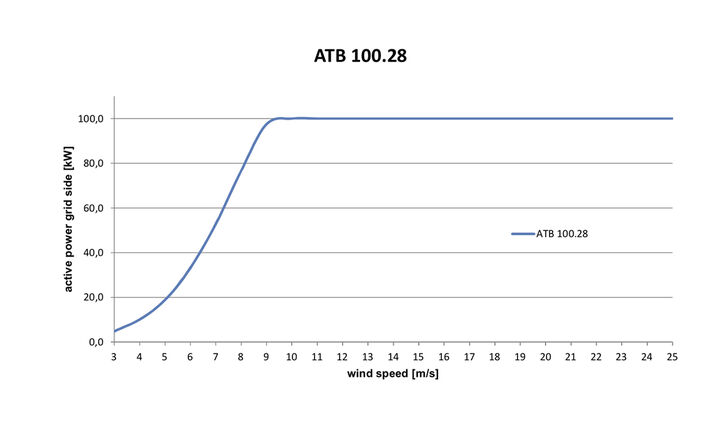

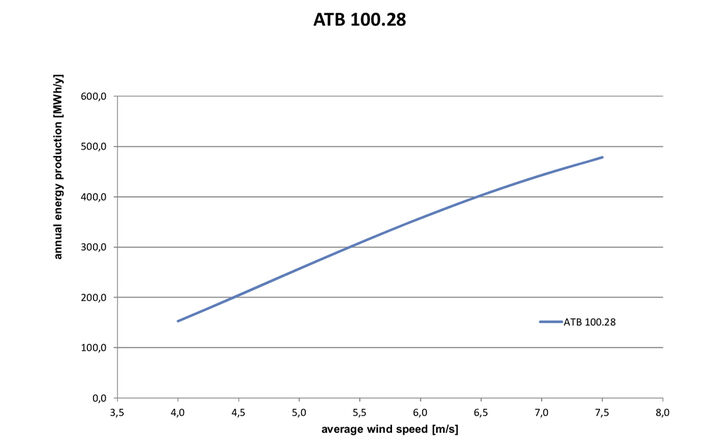

An innovative system that allows the machines to achieve maximum energy efficiency and high performance.

Our experience in the wind energy sector dates back to the 80's when Riva Calzoni in Bologna, in collaboration with the German company MBB (Messerschmitt-Bolkow-Blohm), developed one of the first wind turbine generators in Italy. M30 was a single-blade turbine with a pitch control system which represented an innovative design at the time.

Since then, we have always maintained the interest and enthusiasm that led us, in 2012, to return into the wind business market with “under 1 MW wind turbines”, acquiring a share in S&G Engineering GmbH, a German company well-known for its wind turbine technology.

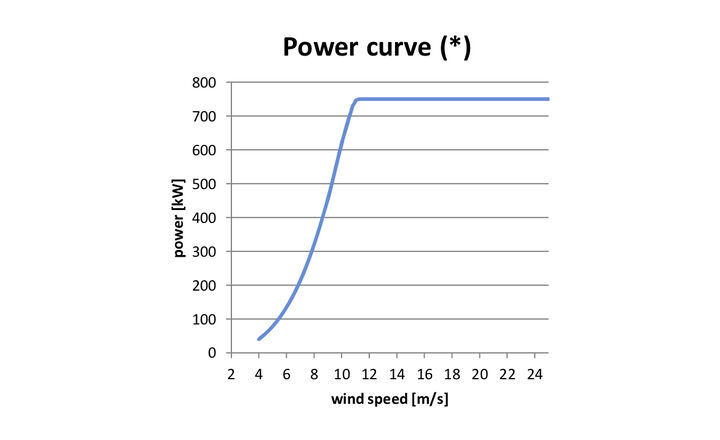

Our technical breakthrough is based on a unique hybrid concept which combines the advantages and simplicity of a robust German engineered gearbox with a high-speed synchronous permanent magnet generator, leading to an optimal generation output.

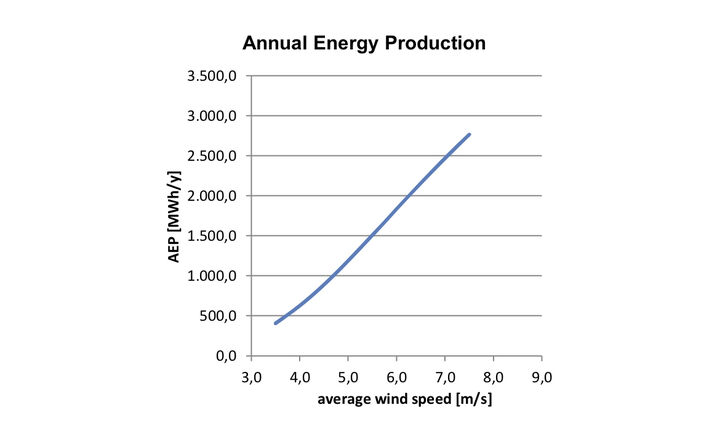

Our turbines have a state-of-the-art pitch control system, an oversized rotor to capture more energy even at low wind levels.