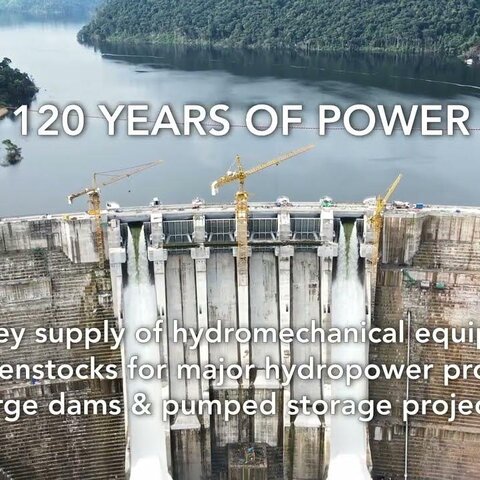

HYDRO MECHANICAL EQUIPMENT SUPPLIER

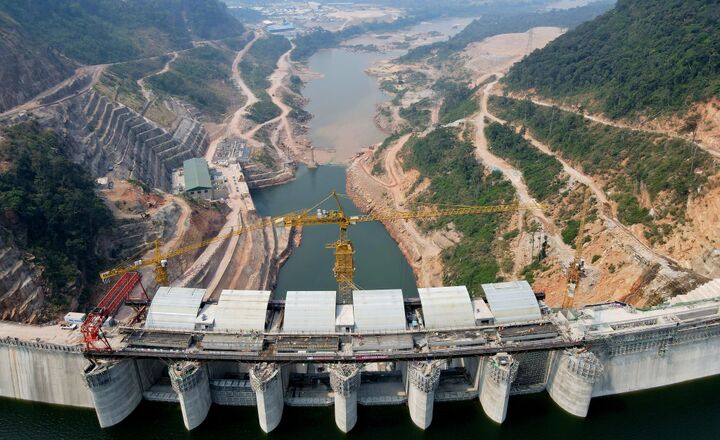

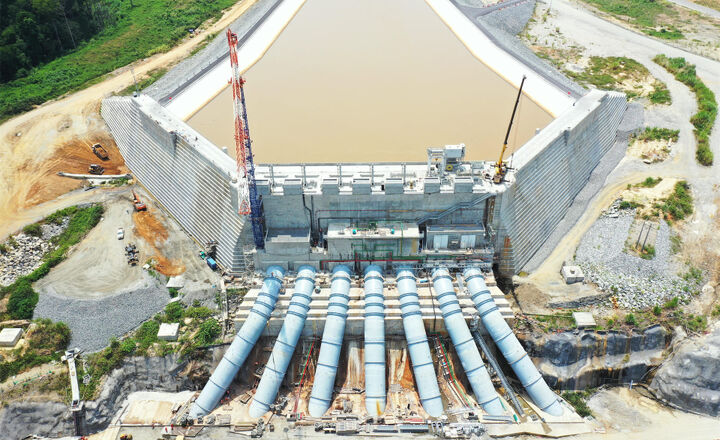

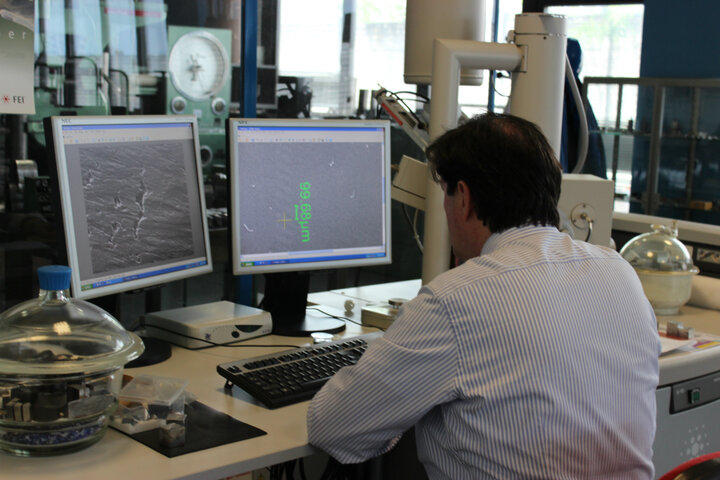

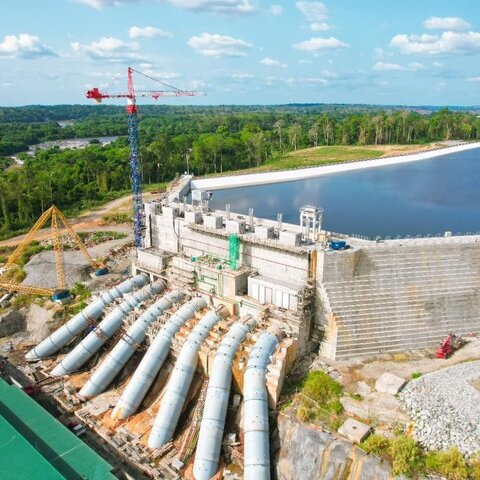

For over a century we have been a leader in design, manufacturing, supplying, installation and commissioning Penstocks and Hydromechanical Equipment for hydropower projects.

ATB Group is now recognized as one of the most qualified international manufacturer companies in providing the following equipment on a “turnkey” basis:

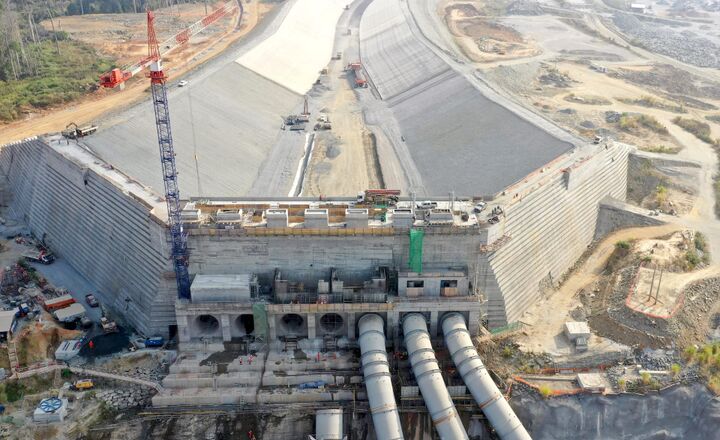

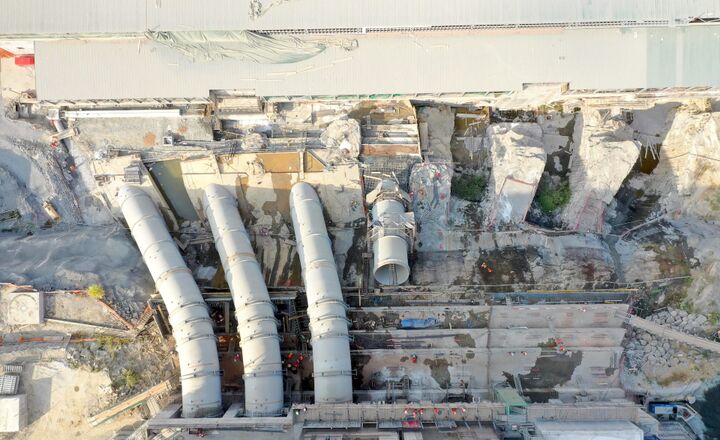

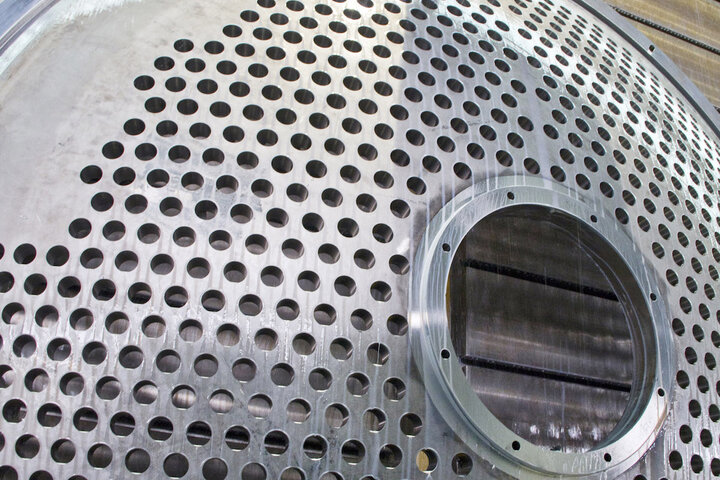

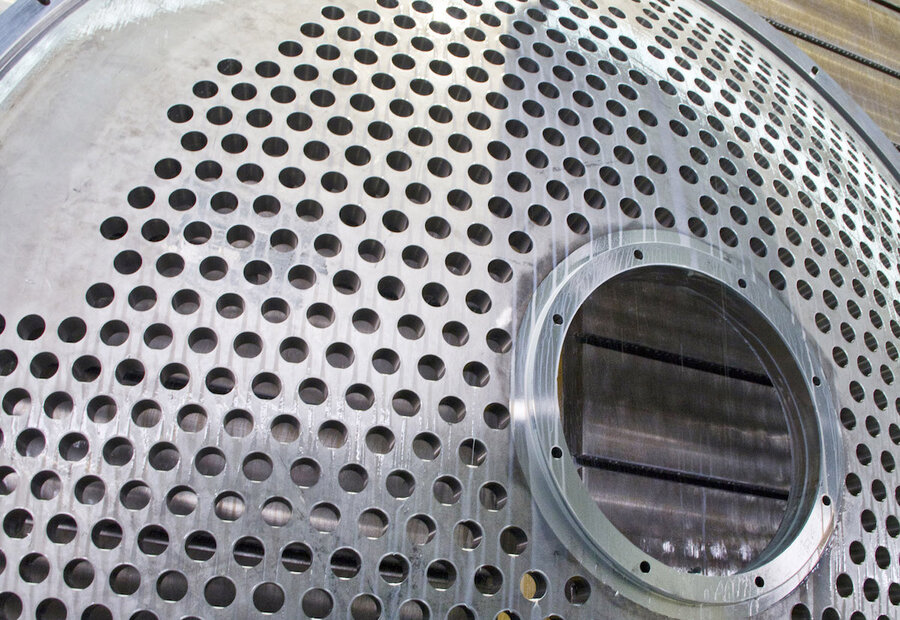

- Steel penstocks, linings, bifurcations and manifolds

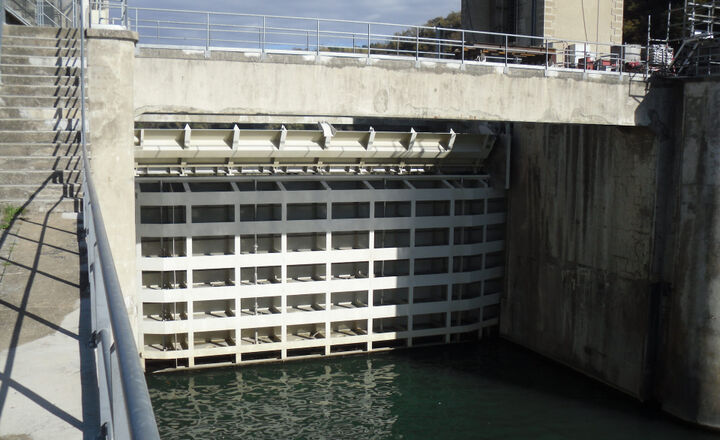

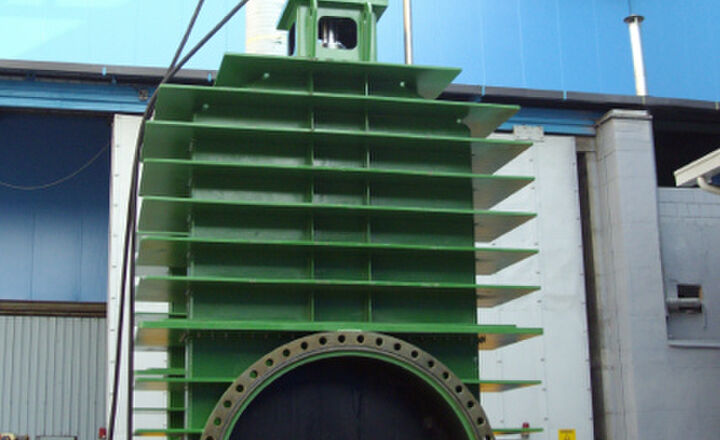

- Spillway and bottom outlet radial gates, fixed-wheel gates, sliding high pressure gates; all equipped with the relevant operation and control equipment

- Butterfly valves, energy dissipating valves, and regulating valves

- Trashracks

- Stoplogs

- Cranes and accessories